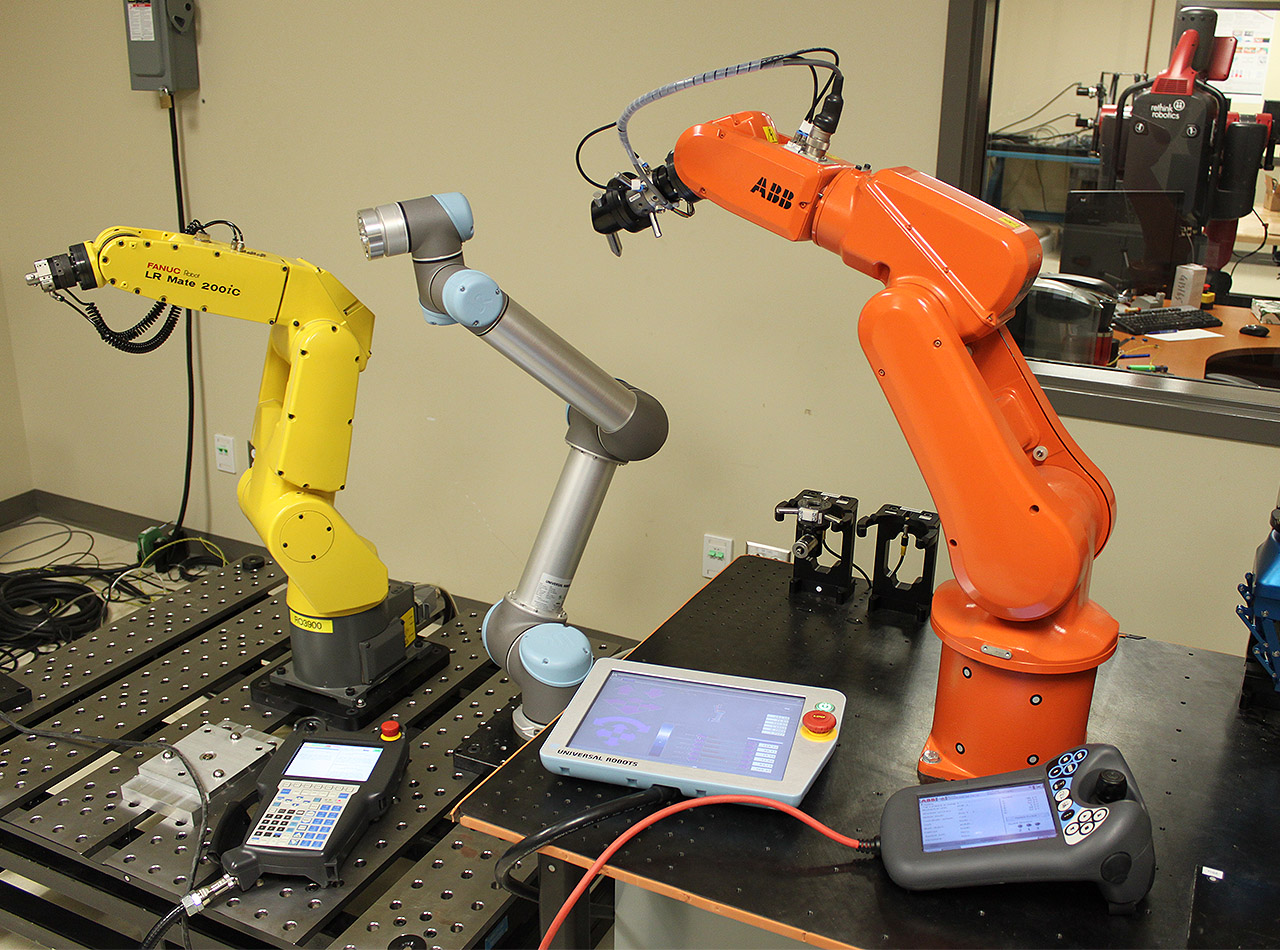

By 2014, China is expected to be the largest consumer of industrial robots, a striking development being driven by rising wages in that country. According to the International Federation of Robotics, 22,577 industrial robots were installed there in 2011, compared to only 14,978 in 2010 and 5,000 in 2009. Some of the world’s largest industrial robot manufacturers — FANUC, ABB, KUKA, and Yaskawa — have set up production units in China. ABB Robotics, for example, celebrated production of their first 100 robots at their plant in Shanghai in as early as 2005. In 2009, their Chinese R&D team even developed a brand new robot, the IRB 120, which I happily use in my undergraduate robotics course. KUKA alone, which enjoyed a 16% market share in China in 2011, claims to have sold more than 7,000 robots in that country. The Chinese have now established their own robot manufacturers. ESTUN Robotics, headed by a bright former fellow student of mine (Dr. Jiegao Wang), is one of these, as is GSK CNC Equipment. However, it wasn’t until July, 2011, that speculation began about the ways in which robots would replace workers in China.

By 2014, China is expected to be the largest consumer of industrial robots, a striking development being driven by rising wages in that country. According to the International Federation of Robotics, 22,577 industrial robots were installed there in 2011, compared to only 14,978 in 2010 and 5,000 in 2009. Some of the world’s largest industrial robot manufacturers — FANUC, ABB, KUKA, and Yaskawa — have set up production units in China. ABB Robotics, for example, celebrated production of their first 100 robots at their plant in Shanghai in as early as 2005. In 2009, their Chinese R&D team even developed a brand new robot, the IRB 120, which I happily use in my undergraduate robotics course. KUKA alone, which enjoyed a 16% market share in China in 2011, claims to have sold more than 7,000 robots in that country. The Chinese have now established their own robot manufacturers. ESTUN Robotics, headed by a bright former fellow student of mine (Dr. Jiegao Wang), is one of these, as is GSK CNC Equipment. However, it wasn’t until July, 2011, that speculation began about the ways in which robots would replace workers in China.

Continue reading →

ABB finally

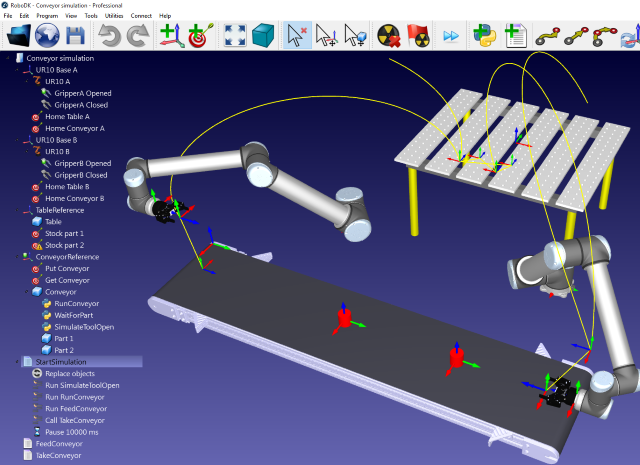

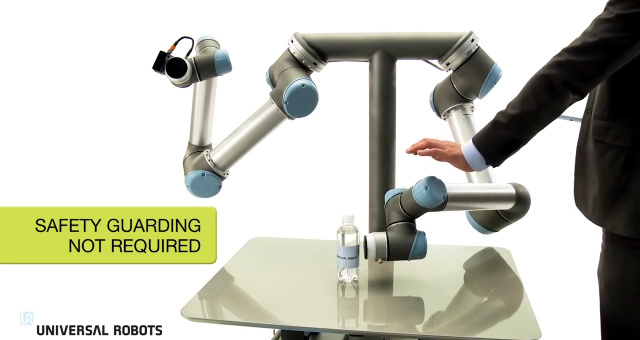

ABB finally  All the stars were aligned for Automate 2015 to be a very exciting industrial robot show. Exhibit space was 80% larger than in 2013. Universal Robots was to showcase its new UR3 collaborative robot. And of course, Rethink Robotics was supposed to unveil its one-armed cobot, Sawyer. But it didn’t. And this probably darkened my perception of the show. (The fact that my first flight was delayed didn’t help either.)

All the stars were aligned for Automate 2015 to be a very exciting industrial robot show. Exhibit space was 80% larger than in 2013. Universal Robots was to showcase its new UR3 collaborative robot. And of course, Rethink Robotics was supposed to unveil its one-armed cobot, Sawyer. But it didn’t. And this probably darkened my perception of the show. (The fact that my first flight was delayed didn’t help either.) Six months ago, after the publication of our revelatory

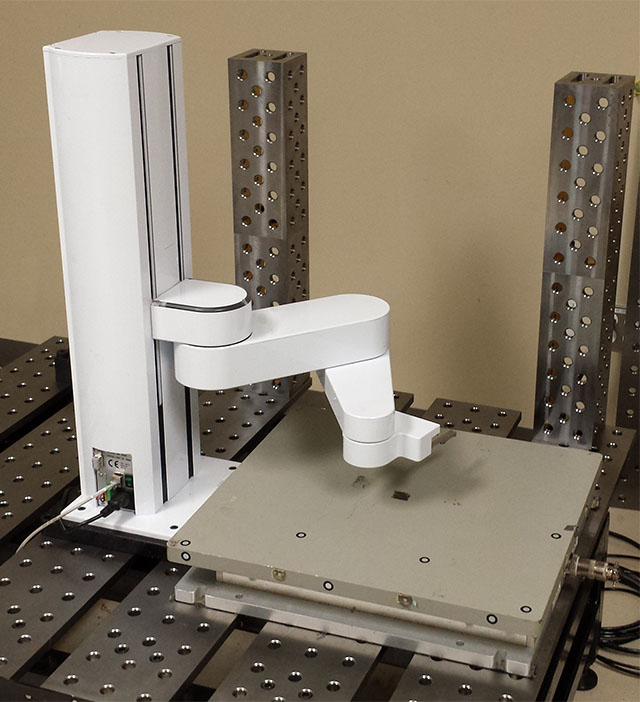

Six months ago, after the publication of our revelatory  Position repeatability is one of the most important performance criteria of industrial robots. The

Position repeatability is one of the most important performance criteria of industrial robots. The  As I listened to a couple of presentations this week in Hong Kong about China’s massive efforts towards building robots locally, I couldn’t help but wonder how would the major industrial robot manufacturers react. Will ABB, FANUC, KUKA and Yaskawa eventually start lowering the prices of their robot arms? In 2013, one fourth of the nearly 37,000 industrial robots installed in China were made by local manufacturers

As I listened to a couple of presentations this week in Hong Kong about China’s massive efforts towards building robots locally, I couldn’t help but wonder how would the major industrial robot manufacturers react. Will ABB, FANUC, KUKA and Yaskawa eventually start lowering the prices of their robot arms? In 2013, one fourth of the nearly 37,000 industrial robots installed in China were made by local manufacturers  There is no doubt that the robot arms of

There is no doubt that the robot arms of  Well, Delta robots may no longer be considered a novelty (at least the visitors of our robotics lab are no longer impressed by

Well, Delta robots may no longer be considered a novelty (at least the visitors of our robotics lab are no longer impressed by

No, Newton’s cradle was not even on my list of candidates, nor any of the other toys on Michael Scott’s

No, Newton’s cradle was not even on my list of candidates, nor any of the other toys on Michael Scott’s  By now, everyone knows that “

By now, everyone knows that “ By 2014, China is expected to be the largest consumer of industrial robots, a striking development being driven by rising wages in that country. According to the

By 2014, China is expected to be the largest consumer of industrial robots, a striking development being driven by rising wages in that country. According to the  RSS - Posts

RSS - Posts